Types and Applications of Sealing Materials

In modern industrial systems, sealing gaskets serve as critical components ensuring the integrity of pipe and flange connections. With the advancement of industry and technology, high-performance sealing gaskets are increasingly being adopted in emerging fields such as new energy vehicle batteries, hydrogen energy, and aerospace.

Definition and Classification of Gaskets

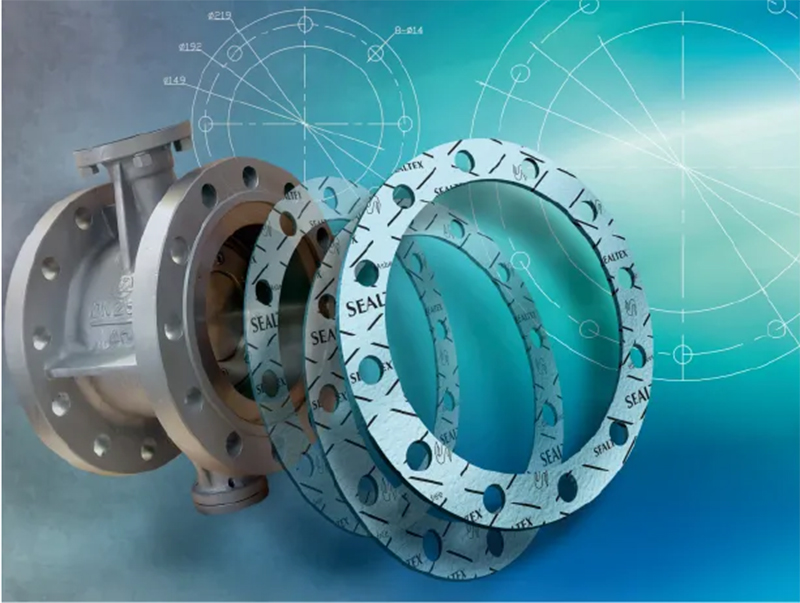

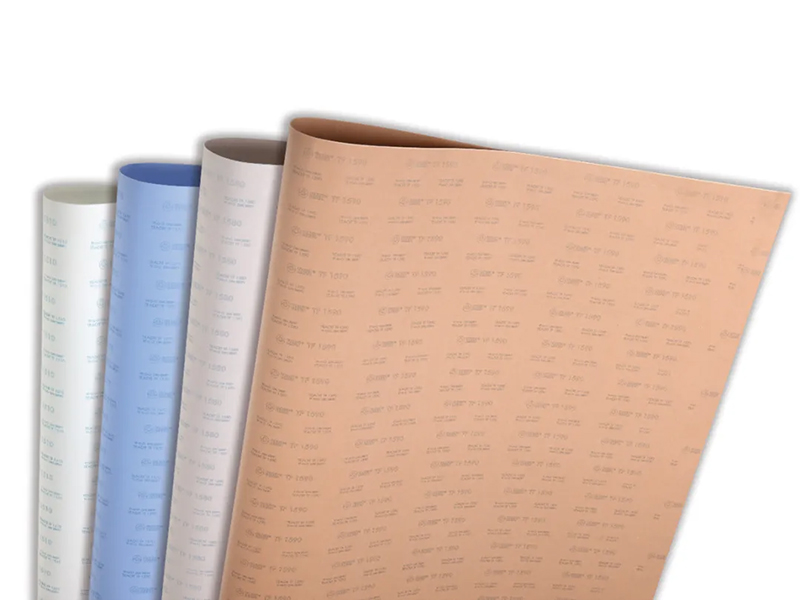

Gaskets, technically referred to as gaskets, are mechanical sealing elements placed between two mating surfaces. Their primary function is to prevent pressurized fluid leakage from the joint while compensating for surface imperfections caused by machining. Based on material and structure, gaskets are primarily categorized into three types: non-metallic gaskets, metallic gaskets, and metal-non-metallic composite gaskets. Our company primarily supplies non-metallic gaskets, including fiber-rubber gaskets, oil-resistant paper, metal-mica composite gaskets, and metal-reinforced graphite composite gaskets.

The selection of gaskets requires comprehensive consideration of multiple factors such as operating temperature, pressure, and medium properties. Among these, the PT value (pressure-temperature rating) serves as the key parameter for evaluating their pressure resistance performance.

The Four Primary Functions of Gaskets

1.Sealing is the core function of gaskets, effectively filling microscopic gaps between mating surfaces caused by imperfect machining to prevent leakage of liquids or gases.

2.The compensating function of gaskets lies in their ability to adjust and adapt to minor surface irregularities and assembly deviations on mating surfaces. Even when flange surfaces exhibit minor scratches or deformations, a properly selected gasket can ensure effective sealing.

3.Vibration damping capabilities are demonstrated in certain specialized applications. For instance, gaskets made from cork rubber or silicone effectively reduce the transmission of vibrations generated during equipment operation, thereby protecting the structural integrity of the machinery.

4.Insulation serves as an added value for certain specialized gaskets. For instance, PTFE gaskets possess excellent dielectric properties, enabling their use as electrical insulators across various frequencies. They are suitable for applications such as electrical instrument insulation.

Traditional industrial applications

Traditional asbestos-containing rubber gaskets were once widely used for sealing steam, water, gases, and oil-based solvents. Due to health and environmental concerns, they have gradually been replaced by asbestos-free materials. SealTex has been committed to providing customers with eco-friendly, asbestos-free sealing gasket materials for over 20 years.

In industrial pump valves and petrochemical industries, sealing for equipment such as pipelines, pressure vessels, reactors, storage tanks, and ball valves must withstand high temperatures, high pressures, and corrosive media, demanding exceptionally high performance from gaskets. Our company supplies corrosion-resistant, high-temperature-resistant, and creep-resistant expanded PTFE and modified PTFE products, such as TEADIT 24SH expanded PTFE, TF1570 glass microsphere-modified PTFE, TF1580 barium sulfate-modified PTFE, and TF1590 silica-modified PTFE.

Expanding Applications in Emerging Fields

With the rapid development of new energy vehicles, battery pack sealing has emerged as a new application area for gaskets. Battery systems require protection against coolant leakage and must maintain airtight integrity, imposing new demands on gaskets' temperature resistance and chemical stability. Hydrogen energy equipment represents another frontier for gasket applications. Hydrogen molecules are extremely small, prone to leakage, and possess flammable and explosive properties, necessitating specialized gaskets to ensure system safety. The extreme environments of aerospace applications present unprecedented challenges to gasket performance, including demands for extreme temperature resistance, radiation resistance, and lightweight construction. Currently, several of our product models are actively exploring applications in these new fields, such as the thermal protection material ST-3271 for aerospace fairings.

For sealing gasket solutions related to hydrogen energy applications, please refer to:新能源氫能行業(yè)用密封墊